Main image: Smoke rises from cork being boiled at the factory. (Jose Sarmento Matos for The Washington Post).

Cork is a natural material known since Antiquity (Phoenicians and Greeks), mainly as a floating material as well as a sealant for bottles and jars. However, it was only in the late 19th century that people began to understand some of the many other attributes of this unique material.

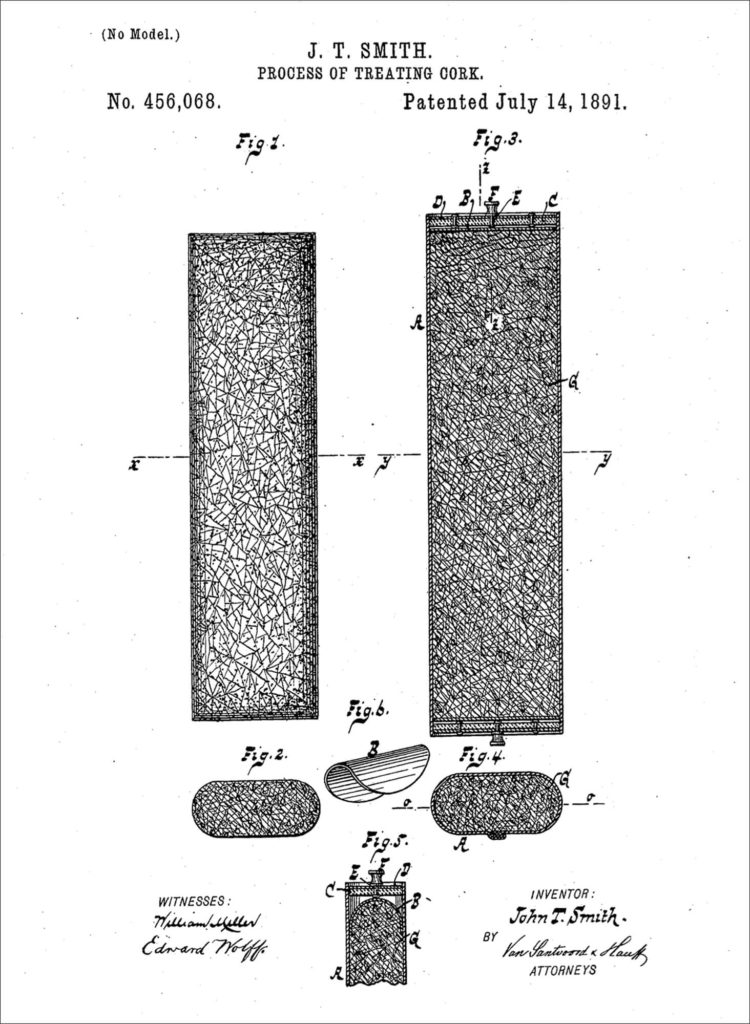

One cork product in particular: Expanded Cork Agglomerate was discovered by accident by a US lifejacket manufacturer John Smith of New York who patented the product in July 1891:

In those days lifejackets were made using canvas vests filled with cork granules in tubes or metal cylinders which kept the canvas stretched, until the filling was finished. One night, a cylinder filled with granules was forgotten and accidently rolled into a boiler.

The next day while cleaning out the furnace it was discovered that the heat had not consumed the cork inside the tube, but rather had turned the granules into a perfectly aggregated dark brown cylindrical mass. Heat in the furnace had expanded the granules, which compressed and became a solid block agglutinated by the natural resin in the cork.

Picture: https://www.corklink.com

Nowadays Expanded Cork Agglomerate, commonly known as Insulation Cork Board (ICB), is produced by exposing the cork granulate (without any additives) simultaneously to a temperature of 335 ° C and a pressure of 0.5 Kg / cm2 for 20 minutes.

In this process, the cork granulate expands, (i.e. the free spaces between the individual granules are closed by the natural binder (suberin) of the wood material which is released in the process), and is formed into agglomerate blocks.

The material is odourless and resistant to insects and rodents. Expanded cork does not age, which means that it maintains its properties while maintaining dimensional stability over the years.

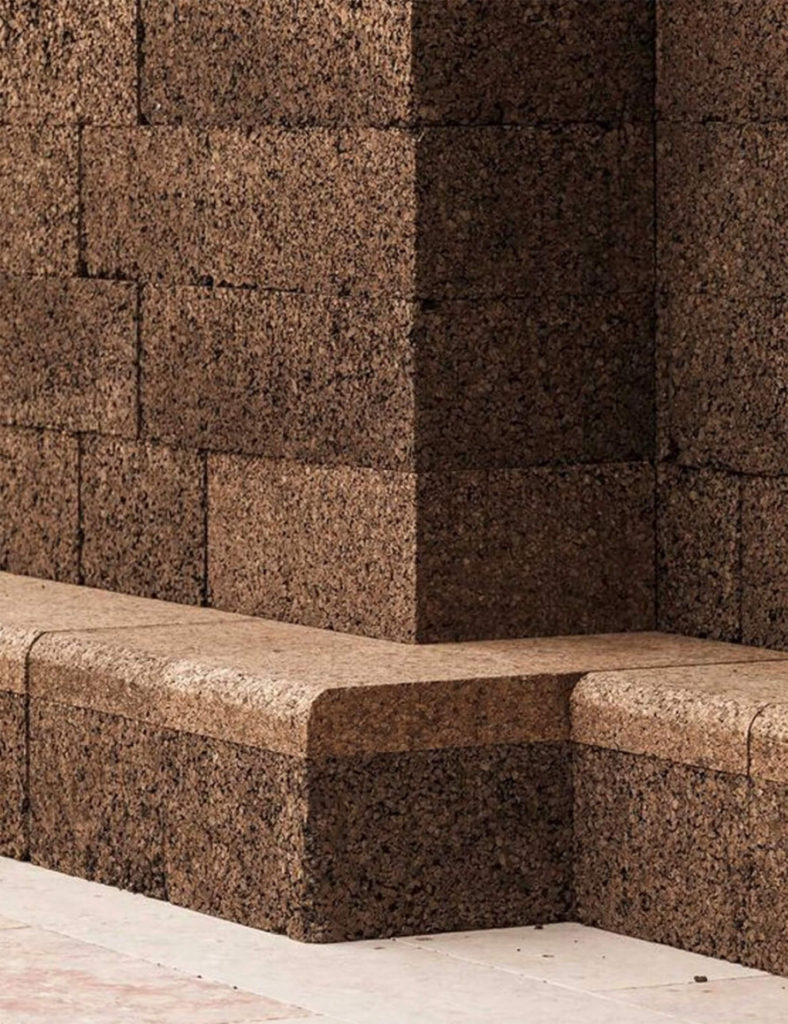

Expanded Cork for insulation on Buildings. Picture: https://www.portuguesetreasures.com

Because every cubic centimetre of cork contains approximately 40 million cells filled with microscopic amounts of air containing nitrogen and oxygen, it came to be realised that cork could also act as an insulator against temperature and sound.

Expanded Cork board for Insulation. Picture: https://www.make-it.london/

Because of this, the building industry is now using more and more cork as architects seek to make buildings more energy efficient and use eco-friendly materials for insulation and to dampen sounds.

Expanded Cork for acoustic insulation and decoration. Picture: https://sound-zero.com/

Expanded Cork furniture. Picture: https://www.arteficius.com

The cork reduces the propagation of surface and impact sounds. In the event of a fire, expanded cork does not emit any toxic gases. The material is completely recyclable and can be reused in construction. It is now used all over the world in the building trade for its thermal, acoustic and anti-vibration properties as well as its resistance to fire.

This super-material is also appreciated more and more for its numerous other advantages: in addition to being a natural, biodegradable and renewable material, it is also a CO₂ sink, playing a key role in helping the environment.

For more information on how Expanded Cork is made today: https://youtu.be/yCCXQ-9uNW8